2025 and what’s next for 2026

52 ISSUES OF CURATED LATER

LESSONS LEARNT FROM TEACHING SEWING

This year I was really excited to start teaching a new-to-me subject at the university where I teach on a casual basis (University of Technology Sydney) - first year construction. Where our students learn to sew on industrial machines. Many of the students were learning to sew for the first time, while others had sewn on domestic machines before.

As we’ve just finished the semester, I thought it would be fun to reflect on a few of the things I learned (or re-learned) through teaching this subject this year as I think they apply to all of us as makers.

Perfectionism kills the process

This is one that I have battled up against my whole life, but somehow seeing others do it made it much more obvious that it’s no good! Some of the students were so fixated on getting everything right, that they just couldn’t enjoy the process. They spent much of the lessons feeling stressed and overwhelmed and trying to see into the future, rather than just giving the technique a go and learning from the process. Some students would come to me with the tiniest mistake or wobbled stitches to ask what to do. I enjoyed being able to support them and encourage them that it’s okay. That’s what we are there for and it will improve with practice.

My partner is Spanish, so in our house we often say “no pasa nada” (no problem) to our toddler as we teach her what’s worth worrying about and what isn’t, and I found myself wanting to say it to my students. Stressing about what is not quite right really takes the focus away from what you did well.

Ask if you need help instead of trying to figure it out on your own.

One of my students wasn’t the best sewist in the class, but she was always going at a solid speed, getting through her work and not getting left behind. One of the people sitting next to her asked her how she was always managing to keep up with things (they are super fast-paced classes), even when she made a fairly big mistake. I answered for her - she always came to me or my assistant to ask for help when she wasn’t sure about something. She didn’t mess around trying to figure it out herself or needed clarification. She also didn’t bother asking her peers to help her (which often leads to a handful of students going down the wrong path together). She never felt like a question was a stupid question (no question ever is) and it meant she learned fast and her skills improved quickly.

There is a right and a wrong way to cut

I would often see my students struggling with cutting their fabric or placing pins. These things might feel like they come intuitively to you, but they are something that needs to be learned.

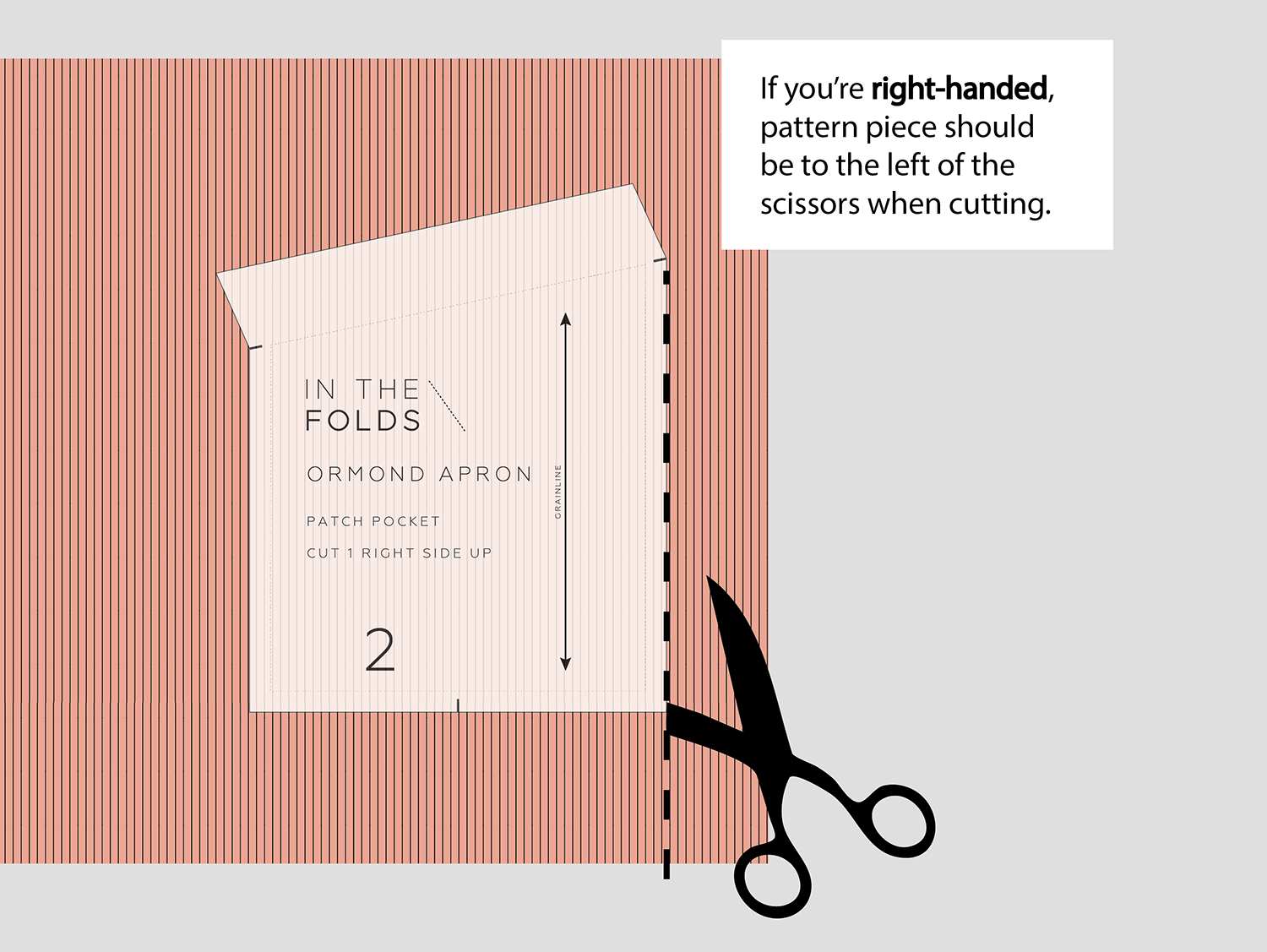

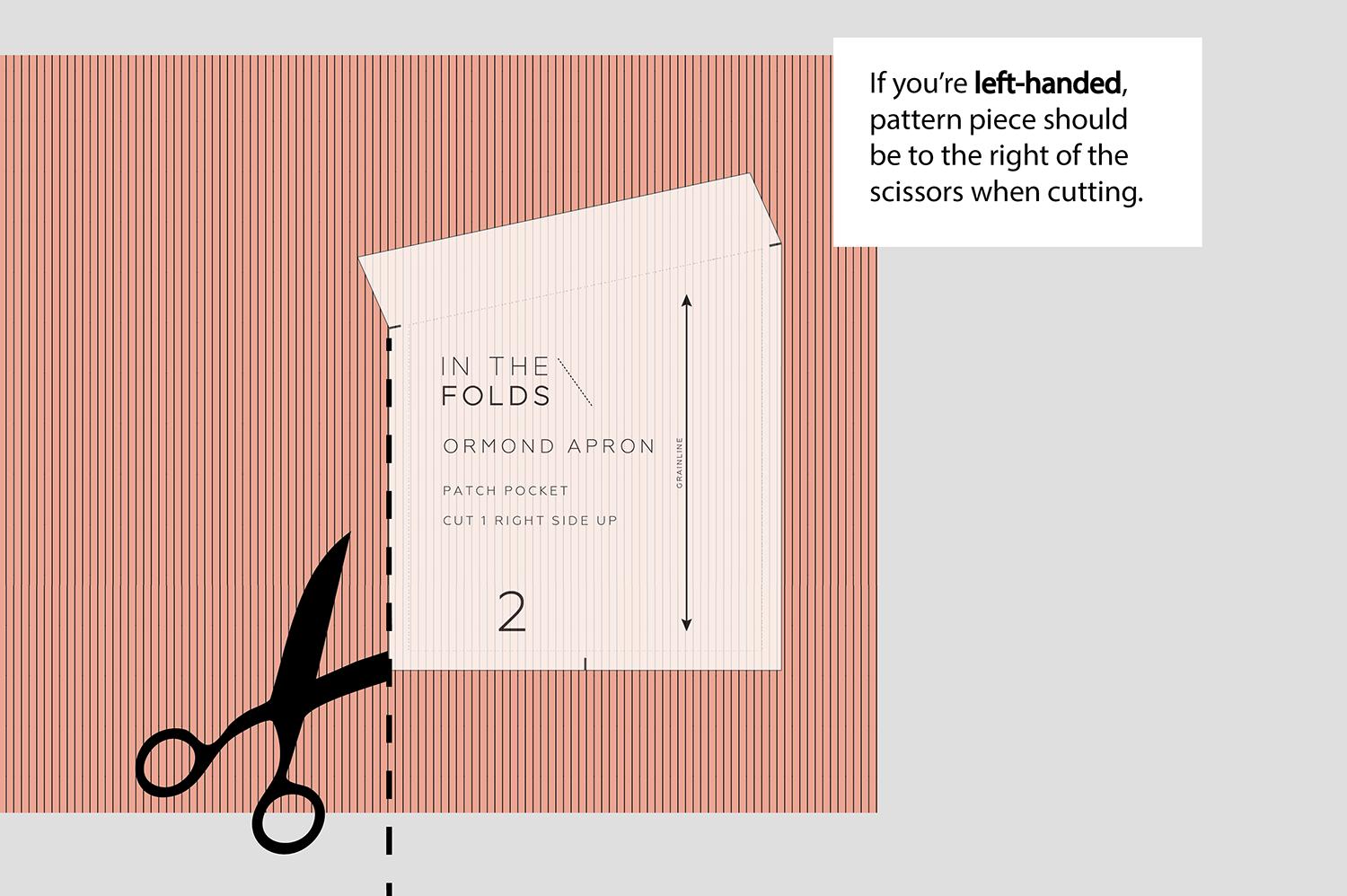

If you’re right handed, cut with the pattern piece to the left of the scissors. If you’re left handed, do the opposite. Use your hand, or pattern weights, to hold the piece in place as you cut. Cut with long cuts, rather than small snips. Cutting like this means you can clearly see the edge of the pattern and can use your other hand to support the fabric and pattern piece. If you are finding it difficult to get to certain parts of the pattern piece to cut in this way, loosely cut around the piece so you can rotate the piece to get into a comfortable position.

Right handed cutting

Left handed cutting

The moment I switched the direction they were cutting or where their pins were placed (pin heads should be placed perpendicular to the seam edge with the pin head facing your dominant hand so they can be easily removed as you sew) I would see a lightbulb turn on as things suddenly became a lot easier for them.

Pins on the right side

Find a way to indicate the right and wrong side

Marking the right and wrong side of the fabric is very important - particularly when working on asymmetric garments. I like to use crossed pins on the right side, but masking tape also works.

Measure twice, cut once.

Sometimes when students were rushing to get everything done, I’d see them make very silly and annoying mistakes. Like cutting the wrong sleeve for the wrong pattern etc. It’s worth staying organised and double checking that you are cutting the correct pattern pieces.

You can have access to too much information.

This is one I think we are all suffering from. We have so much information at our fingertips, that instead of just getting on with the task and giving it a go we often find ourselves getting stuck in research or planning mode.

Some of my students were so worried they were going to struggle with a technique that they would film me doing the demonstration, and therefore be paying attention to the filming instead of the actual demonstration.

Take your time. Rushing toward a deadline is rarely going to lead to good outcomes

This one is a difficult one to impart on students who have so many competing deadlines and are new to university, but your work really does suffer when you’re struggling to meet a deadline. Especially if you’re doing something new!

As we are home sewists, we have the luxury of not sewing to a deadline, so I think it’s important to avoid them whenever we can so we can actually just enjoy the process!

Find a trusted source and follow it

This is something I really enjoyed when teaching - we would teach a specific way to do a technique and then have everyone do it the same way.

As a home sewist it can be overwhelming to see how many ways there are to do particular techniques. I suggest sticking to a few trusted sources for information and then just blocking out the rest of the noise. If you have a certain way of doing things that work for you, don’t reinvent the wheel!

Take photos of your process so you know how to do it next time

A big part of the assessment process is to document the process of making a garment - taking step by step photos along with notes and reflections. I think this is something we could all learn from as it’s a great way to look back at how much you’ve improved, but also a handy reference when making a garment a second time or referring back to a particular technique.

Mark things correctly and accurately

A lot of our students were a bit too happy to use a thick marker when tracing patterns or fabric. Please never do this! When tracing patterns, the thinner the pencil, the better.

Have the right tools

Trying to make do with the wrong tools, really slows you down and impacts your accuracy. I am an advocate of keeping your kit as simple as possible, but you do really need to have some sharp fabric scissors, a pair of snips (even better - put them on a rope around your neck so you always know where they are), pins and something to hold them in, and some accurate marking tools.

Do a practice run

For most of the garments we sewed this year, we sewed a toile before we made the real thing. This wasn’t to check the fit (everyone sews the same garments in the same size) but to have a practice run at all the techniques.

If you are sewing something new to you, it’s worth sewing a toile to both check the fit and to try out any new or tricky techniques.

Those who come clean, learn more

Don’t be embarrassed to say you’ve made a mistake or don’t know how to do something! This is something I have also seen in our Mighty Networks group… when you come clean, people rally beside you and offer words of wisdom and support. If you can’t say you need help, no one will ever know!

Happy sewing,

Emily

MAKER Spotlight: DEBORAH’S scrappy quilted Ormond chore coat

We’ve always got one eye open for Curated by ITF member creations we can share in our Spotlight posts that might spark some creative inspiration in someone else.

This week we’re excited to share what Deborah made using our Ormond coat pattern!

Deborah has been a Curated member for a while now. She first joined way back at the start of 2022 with the release of our Sawtell top pattern. Since then we’ve loved seeing her share her makes, ask questions and just be a wonderful community member all round. But what we’ve loved most of all is how she embodies the essence of In the Folds - that of slow and steady skill-building while making clothes she loves to wear.

This essence is perfectly expressed in her Ormond coat journey. With her first Ormond make she focused on the skills, and then with her second Ormond make she took the opportunity to add her own spin - and we love it!

WHAT DEBORAH SAID ABOUT HER FIRST ORMOND COAT

“I finally finished my Ormond coat! Such a great pattern, the collar sewed up beautifully, and I made a size F with a few cms off both the length and the sleeves.

I learnt so much:

Sewing with heavy duty fabric

The vent and the pocket techniques, so much fun and came out so well, especially after practicing on the apron

Sewing fabric with a nap

This project took many months, mainly because of a kitchen renovation and after toiling I took ages to decide on fabric…. This is Merchant and Mills cotton twill 410gsm in Otto green from Pattern Scissors Frock. I’m glad I took so long because this fabric is amazing to wear. Lovely and stiff, so holds the shape to make it look more like a cocoon coat from the back, and yet soft to the touch with a wonderful nap that is very luxurious.

I also took ages to decide on buttons and then I just went with a simple plain black to keep it classic.

The buttonholes are not great looking, they are even and straight but I think I need that anti-fraying stuff, or I need to go over them by hand. Otherwise, definitely one of the best things I have ever made!!”

DEBORAH’S SCRAPPY QUILTED ORMOND CHORE COAT

Deborah’s Ormond coat journey didn’t stop there. And to be honest, it’s a trait that many of our Curated by ITF members have - the desire to get the most they can out of each pattern the own.

We love how thrifty Deborah was with the project, using up what she had and figuring out how to make it work. If you’ve got a pile of fabric scraps you’d like to make use of, this could be your next project!

Here’s what Deborah shared about her second Ormond coat in our private, online Curated community.

“I have been trying to use up lots of scraps lately and had slowly been working on some random scrap quilt blocks. I recently turned them into and Ormond shirt jacket.

This probably took about 4 months all up.

I like the back better than the front. I actually used an old toile of Darlow pants for the sleeves when I ran out of matching smaller scraps. Still not sure if a single piece for the collar was the best idea..

Things I changed to make it work:

Just used binding around the neck, front centre and bottom as well as the sleeve, instead of the facings.

Did a sort of faux flat felled seam on the interior. A normal seam, trimmed down and then hand sewn to the lining so you can’t see it on the front.

Used giant press studs instead of button holes in case I want to wear it inside out.

No top stitching, the quilting stitches were enough.

The inside is a black cotton voile/lawn. I used up binding I had.

If you’ve made something particularly inspiring from an In the Folds pattern, we’d love you to share it with us so we can share it with our community! Send us an email, or tag us on Instagram @inthefolds.

BEHIND THE SCENES: WHAT'S IN EMILY’S SEWING KIT

Have you ever peeked inside someone else’s sewing kit?

It’s kind of like a window into another person’s creative soul. No two kits are the same, and that’s exactly what makes them so fascinating.

At first glance, a sewing kit might look like a practical jumble of tools, threads, and fabric scraps. But dig a little deeper, and you’ll discover it’s shaped by the person who uses it—their go-to techniques, their favourite fabrics, the patterns they return to again and again.

Whether it’s packed with vintage notions, colour-coded bobbins, or a well-worn pair of snips that just feel right, each kit tells a story of experience, experimentation, and personal style.

In this behind-the-scenes peek, Emily opens up her sewing kit to share what’s inside. From must-haves to little quirks, here’s what she reveals!

What’s inside Emily’s sewing kit

The contents of Emily’s sewing kit is very much geared towards teaching sewing at university and working in her sewing pattern design studio.

In order for her to do what these tasks require, here’s what she always has to hand through her trusty sewing tool kit:

snips, on a lanyard or ribbon so she can wear it when she’s working

scissors (paper AND fabric)

unpicker, which may not get used that much, but is good to have to hand

machine tweezers

curve measuring wheel

tape measure

small clear ruler

seam gauge

eraser

Pacer pencil + leads

spool of thread

tracing wheel

corner turner

silicon tip tool

clear "magic" tape

notcher

pin cushion

post-its

chalk liner

markers and pens

stiletto / awl is supposed to be in there!

We also shared a reel on Instagram where she talks through the contents of her kit. You can watch it here.

If you’re not drafting or designing sewing patterns like Emily is, you may find that this version of a sewing toolkit doesn’t meet your specific needs.

So, how do you figure out what your sewing toolkit should include?

HOW TO PUT YOUR own SEWING TOOLKIT TOGETHER

Most sewing kits don’t come together overnight. It takes time (and a few trial-and-error purchases) to figure out which tools truly deserve a place in your kit.

Some makers swear by a specific chalk pencil or seam ripper, while others discover their ride-or-die tool by accident—usually mid-project, when they reach for the same thing again and again.

For example, Emily has post-its in her sewing kit. This might not be something you will EVER use when sewing, but Emily needs to be able to make notes on the run, and post-its are what works for her.

Experience (which requires time!) plays a big role in figuring this out, but so does curiosity.

You might pick up a tip from a sewing friend, fall in love with a tool recommended in a tutorial, or stumble across something in a haberdashery store that you didn’t know you needed until you used it once.

Building your kit is part of building your skills—and there’s no one “right” way to do it. It will happen as you practice and one day you’ll look down and realise you’ve assembled a complete sewing toolkit that has exactly what you need, when you need it!

Have you already got a tried and true sewing kit that you take with you everywhere? We’d love to hear what it includes!

Spotlight: Failing Forward - What it really means for makers

We recently saw a comment from one of our members pop up in our Curated by ITF community that stopped us in our tracks:

““I embodied the motto ‘failing forward’ over and over again while doing this. Every time it didn’t work, I learned something, and by the end (is there ever actually an end?) I ended up with things that fit and I learned SO SO MUCH about pattern drafting and alterations. Absolutely priceless! Is it easy? No, I won’t tell you that, but it’s very doable and totally worth it.””

At In the Folds, we often talk about sewing as a practice, not just a product or outcome.

And this? This is the practice in action. Failing forward isn’t about avoiding mistakes - it’s about moving through them with curiosity. It’s about learning, not just making.

We did a little digging to understand where this term came from.

What does ‘failing forward’ actually mean?

The term was popularised by leadership expert John C. Maxwell in his 2000 book Failing Forward: Turning Mistakes into Stepping Stones for Success. The central idea is that failure isn’t the opposite of success. It’s part of it. What separates people who grow from those who stay stuck is how they respond to things going wrong.

Maxwell writes: “The difference between average people and achieving people is their perception of and response to failure.”

And this mindset? It applies just as much to creative practice as it does to leadership. Whether you’re learning to alter a pattern, trying a new technique, or sewing with a tricky fabric for the first time, let me tell you, there will be stumbles. The key is to see those moments not as setbacks, but as progress.

What failing forward might look like in your sewing practice

A crotch curve that doesn’t fit correctly the first time?

Call it a wearable toile and do some experiments with altering the curve. Or the many other things you can do to alter the outcome of a crotch curve.

A garment that looks nothing like you imagined due to the drape of the fabric?

Now you understand more about fabric and how it drapes on the body.

A bodice that doesn't quite fit?

Now you know where to adjust in future.

A tricky fabric that ends up puckered or stretched?

Next time, you could try a different needle or seam finish.

A fly that you sew 15 times… (Can you tell I am speaking from experience?)

It leaves you knowing you chose the best technique to use going forward.

Each of these ‘failures’ moves you forward—if you let them and don’t give up!

There’s No Final DESTINATION CALLED SEWING Mastery

Rachael, the Foldie who said this in our group to encourage the community, said it perfectly: “Is there ever actually an end?”

Sewing, like any craft, is an ongoing relationship. You’re never done learning. I’ve been at it for 28 years and I am still learning daily!

But that’s the point, right? There is no finish line, only a deeper understanding of the process, your preferences, and your skills.

I see this in our community every day. Makers who keep showing up. Who ask questions. Who try something new, even if it doesn’t go perfectly. Who make mistakes, but keep making.

That’s what Curated is all about.

Not the end result, but the steps we take to create a garment.

The trying. The tinkering. The learning.

So if you’re feeling stuck, or like something just didn’t work the way you hoped, remember this: you’re not doing it wrong. You’re doing it bravely. You’re doing it honestly. You’re moving forward, even if it doesn’t feel like it most of the time.

Keep up the great work!

Emily

BEHIND THE SCENES: EMILY'S SEWING STUDIOS

As it’s Make it With us in May—our annual time to revisit the In the Folds pattern archive—I thought it would be fun to show you where all that work has come to life over the years.

I recently moved house, and with that decided it was time to bring my studio home. It had been a long time coming, and something that I had remained in denial about since having my daughter at the end of 2022. But my way of working was no longer sustainable.

I will introduce you to my studio today It’s nothing fancy, but possibly the most practical studio I have had so far. And I also thought it would be a good time to go back down memory lane through past studios. Each represents a different time in my life and my business… and now that ITF is in its 10th year, there have been a few!

studio 1 - finding my feet

When I started In the Folds, a kind friend allowed me to use a room in his workplace for a few months while I got on my feet. It was nothing fancy as it was temporary, but it gave me a feel for having my own space dedicated to running my new business. It’s where I was when I released my very first pattern - the Rushcutter dress.

Studio 2 - A realisation about what I need and want

I realised after a while that I wanted to be around other creatives, and also needed something more permanent.

I found a small studio in a local creative space that I thought was perfect—close to home, nice people, etc—but after a few weeks, I realised it wasn’t quite the right fit. I was new to the whole studio thing and hadn’t thought about how important natural light was to me, and this place didn’t have much of that. And although the people were lovely, they were barely there and I was often alone in my dark little space.

The only photo I seem to have of this space is me sitting in a space outside of my studio trying to get some natural light to do some hand sewing!

Studio 3 - True friendship and community

After a while I decided it was time for something bigger and brighter. I had met Kate Brookes @sewingwithkate and we decided to find a studio together.

We found the perfect place that was close to home, had great light and great people. This will go down as my favourite studio of all. The woman running the creative space became my “studio wife” and I revelled in having a place where there were like-minded women to speak to every day as we all worked away on creative pursuits. Painters and sculptors worked alongside sewists and patternmakers and we shared the highs and lows of working and living a creative life.

Eventually Kate moved out and I stayed there on my own, expanding to take over more of the space. This studio was also special to me as it’s where I was when I hired my first employee, Alys @unpicked.studio and she became part of this special group of creative women.

This is the studio where I feel my business completely shifted. It went from more of a hobby to a real business, with an employee and solid plan for the future. It is where I was when we launched Curated.

Studio 4 - A house move = a studio move

In 2020, my partner and I felt a yearning for community in a way we hadn’t before then. We were living in the area where I had grown up, but no longer felt like we had enough of a community around us. We decided it was time for a change of scenery, so we moved closer to the city. I was in denial and hoped I could continue traveling to my studio, but over time it became unsustainable so I was back on the hunt for a new home for ITF.

I found a studio through one of my teaching colleagues. She was in a studio in a huge creative space in the inner west of Sydney. I never knew quite how many creatives were in there (20? 30?) but I found a home there in a bright and lovely space. It was a lovely studio with a lovely community and I enjoyed being in the space.

I had my daughter while working in this studio, and I felt a big shift in how I was working. My studio had always been a sanctuary—my space to focus, create, and breathe—but with a breastfeeding infant and very little outside support, it became almost impossible to get there. When I did, it felt rushed and frantic—no longer the calm refuge it had been for so long. Or I’d be there, but have her with me, strapped to me in a carrier or napping in her baby nest on the floor.

It was the first time I’d had to reconsider what being a creative looked like for me, not just in the hours I had, but in the way I worked and how I felt doing it. I ended up working from home whenever I could. Many probably imagine that my workday is all sewing and patternmaking, but it isn’t really. I’d say that about 20% of the time I am working with my hands, sewing and patternmaking, while the rest of the time I am working on my computer - writing patterns, formatting patterns, writing emails, managing my team, researching… and the list goes on.

So working from home has become easier as my job has become more and more computer heavy. I was living in a small one bedroom apartment with my partner and a toddler though, so it was never an option to bring the hands-on side of my business home.

I was in this studio until a huge rent increase on the building meant we all had to move out, which was hard and sad and stressful.

Studio 5 - A realisation that I needed a change

The next studio I found was a studio with 2 of my friends from the place that I had just left. We took a bit of a risk, and due to there not being many affordable spaces around we took a space that was probably a bit small for the 3 of us. We thought that with a bit of space-saving hackery we could make work it work... And we did… Kind of. We all had a corner and managed to fit the necessary things in that we needed.

But I found myself barely going to the studio, instead working from home whenever I could. Parking was hard, the space was small and cluttered and I just didn’t enjoy being there when I did manage to get there. I was working from home more and more. The idea of working from home started to feel less like a compromise and more like a relief.

As our daughter grew and our needs as a family were changing, my partner and I started considering a move a little further out of town but with a bit more space. As soon as we began thinking about this, I realised I was ready for a home studio. I had to stop kidding myself and pretending I would go back to the studio on a more regular basis. It’s easy to get caught up in the idea of what you want life to look like, rather than the reality. The reality was that I was finding it difficult to get myself sorted along with getting my daughter to childcare and then get to my studio. It all was becoming too hard. The thought of being able to get my daughter off to daycare and then wander out to my studio was bliss! The idea that I didn’t have to think about lunch in the morning, could just walk up when I was ready and look in the fridge was what I needed for the season I’m in.

Studio 6 - A home studio for the season

And here I am at studio number 6! In my garage where I can see my daughter playing in the garden and I can run up to the house for a cup of tea. It may not be the most glamorous of all the studios I have inhabited, but it really is the most functional for where I’m at right now.

Each of these studios tells a part of the In the Folds story. Right now, it’s about adaptability, realism, and making space—literally and figuratively—for the season I’m in.

The season when I might need to work after my daughter goes to sleep, or might need to work in my pyjamas, or have a sit in the garden with a cup of tea between projects. It’s the season for accepting the reality of where I’m at and knowing that one day, when my daughter is bigger I may be able to work outside of the house again. But for now, my home studio is just what I need.

Happy sewing,

Emily

Spotlight: Choosing the right project for your skill level (and how to level up!)

With Make It With Us in May in full swing, we’re inviting you to choose any pattern from the In the Folds archive. But with so many options, it can be hard to know where to begin.

So, this month’s Spotlight post is here to help!

We believe that sewing is more enjoyable — and more sustainable — when you meet yourself right where you are, then build your skills slowly and intentionally. Whether you’re just starting out or you’ve been making for years, choosing the right project for THIS moment can make all the difference.

How to find the perfect pattern for where you’re at — and where you’re headed

Here are a few ways to decide what to make this month (or whenever you are looking for your next project):

1. Reflect on your recent makes

What felt really satisfying? What left you stuck or frustrated? Look for a pattern that builds on the skills you already have, with one or two new techniques to try.

The key here is focusing on just a couple of new techniques at a time. For example, when we designed the Darlow bag we knew it had more than a few techniques that would be new to many —the zip insertion, working with hardware and piecing together fairly complex shaped pattern pieces, to name a few! But because it’s a bag and you don’t need to worry about fit. Therefore, it makes sense as a skill-building project that will stretch your skills without completely overwhelming you.

Projects like this or our Hove tote pattern (above) are really good options if you want to sharpen up your precision sewing without worrying about getting the right fit.

2. Start with your strengths

If you’re confident with woven fabrics but new to garment construction, something like the Collins top or Acton dress is a great entry point.

Reach for the Collins top if you prefer not to worry about fit. The shape of it means that most people won’t need to think about fitting alterations. The major fitting alterations makers have made to this pattern are to add length or changing it from a high-low hem to a straight hem.

3. Choose your own adventure

Maybe your goal is to make a matching set, create your first outerwear piece, or try lining a garment for the first time. We say, go for it! Sometimes you just need to take a step of faith and believe that you can do something!

But you don’t have to do it entirely alone. Our patterns and resources are made to support you step-by-step, and our community is here to cheer you on.

4. Sew for the season (or your lifestyle)

Sometimes the best place to start is your wardrobe. Sounds counter-intuitive, right? But considering what you already have is a great place to understand how and what you actually wear!

Start by asking yourself the following questions: What do you reach for often? What are the pieces you’ve noticed are missing from your wardrobe?

Think about designs that will get a lot of wear. Whether that’s comfy culottes for weekend adventures or a crisp button-up for layering, pieces that you can mix and match or layer up and down according to the season will always get more use!

If you need more help delving into wardrobe gaps and how to fill these gaps intentionally, I suggest looking at our Slow Sewing Planner.

5. Ask the community!

If you’re still not sure, why don’t you ask for help in the community group? It’s one thing taking advice from us, but a whole other thing to get advice from people who are just like you!

However you join us this May, we’re so glad to be making alongside you. Here’s to learning, experimenting, and sewing with joy and intention!

Happy sewing,

Emily

When feedback stings: Behind the seams of the Darlow bag

There’s something about receiving negative feedback that really gets me. My stomach drops, my heart races. I know I’m not saving lives — I make sewing patterns! — but I care deeply about the work. People trust me with their time, money, and fabric. I want them to walk away from an In the Folds project not just with a beautiful garment or accessory, but with new skills and confidence.

And yet, one piece of negative feedback can take up more space in my mind than a dozen glowing reviews (thank you to everyone who takes the time to share those, by the way — it truly makes my day!).

Today, I want to share a story about one of those moments — and how it ended up teaching me a lot about process, collaboration, and letting go of perfection.

When a gift becomes a bigger idea…

When we started designing the Darlow bag, we thought it might be our December 2024 pattern — something fun, thoughtful, and giftable. A fun, giftable project that could be made in a few evenings. But as we worked on it, it grew into something else entirely. It was more involved, more skill-focused, and definitely more demanding — not the kind of project we could throw at folks during the December overwhelm.

So we reshuffled our schedule, gave it the time and space it deserved, and dived into the details.

Collaborating across continents

If you read our blog post about making this pattern, you’ll know Alys and I worked on this project across continents. When one of us hit a hurdle, we’d pass the project back to the other to troubleshoot — just like we used to when we worked side-by-side. After lots of back and forth, we landed on a version we both loved. It ticked all our boxes:

Reflected the In the Folds aesthetic

Offered a thoughtful, skill-building experience

Felt exciting for our community

We felt good. Ready. Almost done.

An unexpected setback

To be extra thorough, I decided to get a fresh set of eyes on it — our editor, Lee. She usually edits the instructions each month, so I asked if she’d sew a version of the bag while reviewing the instructions.

Honestly, I thought of it as a precaution — I didn’t expect anything major. Then I got the email:

Hi Emily,

I've made a version of the bag and have a lot of feedback — unfortunately, it's mostly negative. I've made a video to explain my thoughts — it seemed like the easiest way. Have a look and a think — I'm happy to chat further.

Overwhelm hits

I opened the video and almost instantly felt my chest tighten. Lee went into detail of the hurdles she had faced, including recreating the zipper troubles in paper to better explain her point.

But the illustrations were done. The pattern was done. The sew-along was done. I lasted ten minutes before I had to stop. I knew I was too emotionally close to process it clearly.

I sent the video to Alys, who’s excellent at setting aside emotion and focusing on what needs to happen. The next morning, she sent me a Google Doc summarising the key points.

Here’s what stood out:

It wasn’t clear how the bag was intended to be worn.

The zipper opened toward the bottom of the bag when worn on the back and rotated to the front.

The zipper installation was overly complicated and didn’t yield a clean finish.

The strap construction felt unnecessarily complex.

Seeing it written down helped. I could start tackling things, one step at a time.

Small fixes first

The first issue was a simple one: we hadn’t made it clear that the Darlow bag was designed to be worn on the front. Alys and I had always just put it on the “right” way when sampling, without giving it a second thought.

I updated the product description and added technical sketches to show how it’s intended to be worn. I also loaded up my own bag and tested different ways of wearing it — and was relieved to find it still worked well if worn differently.

Rethinking the zippers

The zipper feedback was harder to hear, but totally fair. We’d tried a few different methods during development, and although we liked the result, it was fiddly — and the finish wasn’t quite as clean as we’d like.

With other projects and teaching commitments piling up, I knew I couldn’t take this on solo. So I called in reinforcements.

Enter Melanie

I asked Melanie — a brilliant maker and patternmaker I teach with (and now a dear friend) — if she’d be up for the challenge. She agreed to troubleshoot the pattern from start to finish.

Melanie reworked the zipper installation in a way that kept the spirit of our original design but made the process cleaner and easier. We added fusing strips to help things remain stable.

She also streamlined the strap construction, added a topstitching detail to anchor it better, and helped us realise we’d overcomplicated things trying to make the bag adaptable for all body sizes.

She also suggested adding a pocket to the lining to make it even more functional.

She took photos of every step and made detailed notes — a true lifesaver at a moment when I just didn’t have the brain space to take it all on.

She was also ecstatic about the bag. She wore it to a gig the night she finished it! Having her enthusiasm about the project when I was wading in the messy details of it all gave me a boost of confidence. All was not lost, it just needed some fine-tuning.

Testing it all again

Once I had Melanie’s notes, I started working through the updates. I don’t do the final illustrations, but I can edit them, which comes in handy during tight deadlines or small changes.

Still, I hit wall after wall. I couldn’t tell if the updates worked without sewing them myself. So I did a pocket sample. Then I made a full bag. Sewing the new zip method a second time — especially after the pocket sample — made everything feel smoother. (Even I need the reminder sometimes: doing a practice run is always worth it.)

I photographed the process for the sew-along, updated the instructions, and sent the new version back to Lee for a final check.

What we learned

I’m not going to sugar coat it — this was a slog. It’s disheartening to redo work you thought was finished. But I was also grateful. Grateful we got the feedback in time to fix it. Grateful our customers wouldn’t have to wrestle with the issues our editor faced. And grateful for the chance to reflect on our workflow.

We probably jumped ahead too quickly — the sew-along shouldn’t have been finished before the pattern had been fully tested. That’s a lesson I’m taking forward.

I still hate receiving negative feedback. I still get that stomach drop. But I’m learning that it doesn’t mean failure — it means we’re still in the process.

The Darlow bag is stronger now because of that hard moment. And our systems are a little stronger too. Sometime growth doesn’t feel graceful, but it’s worth it. And, I’ll take that over “perfect” any day.

Thanks for sticking with me, and thanks (always) for supporting In the Folds.

Happy sewing!

Emily

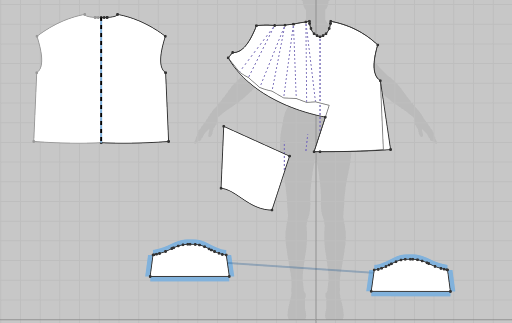

Spotlight: Creating a bag inspired by the Darlow pants

Following the success of our Hove tote pattern release last year, we decided to continue our foray into accessories in 2025. We loved how our community received the idea of new patterns inspired by old, and so we decided to look to our pattern catalogue for inspiration again.

And, because our beloved patternmaker, Alys recently moved back to the UK, we thought we’d share what it’s like to create a pattern design across continents with the help of modern communication channels like Zoom, Google docs and Whatsapp!

HOW THE DARLOW BAG DESIGN CAME TO BE

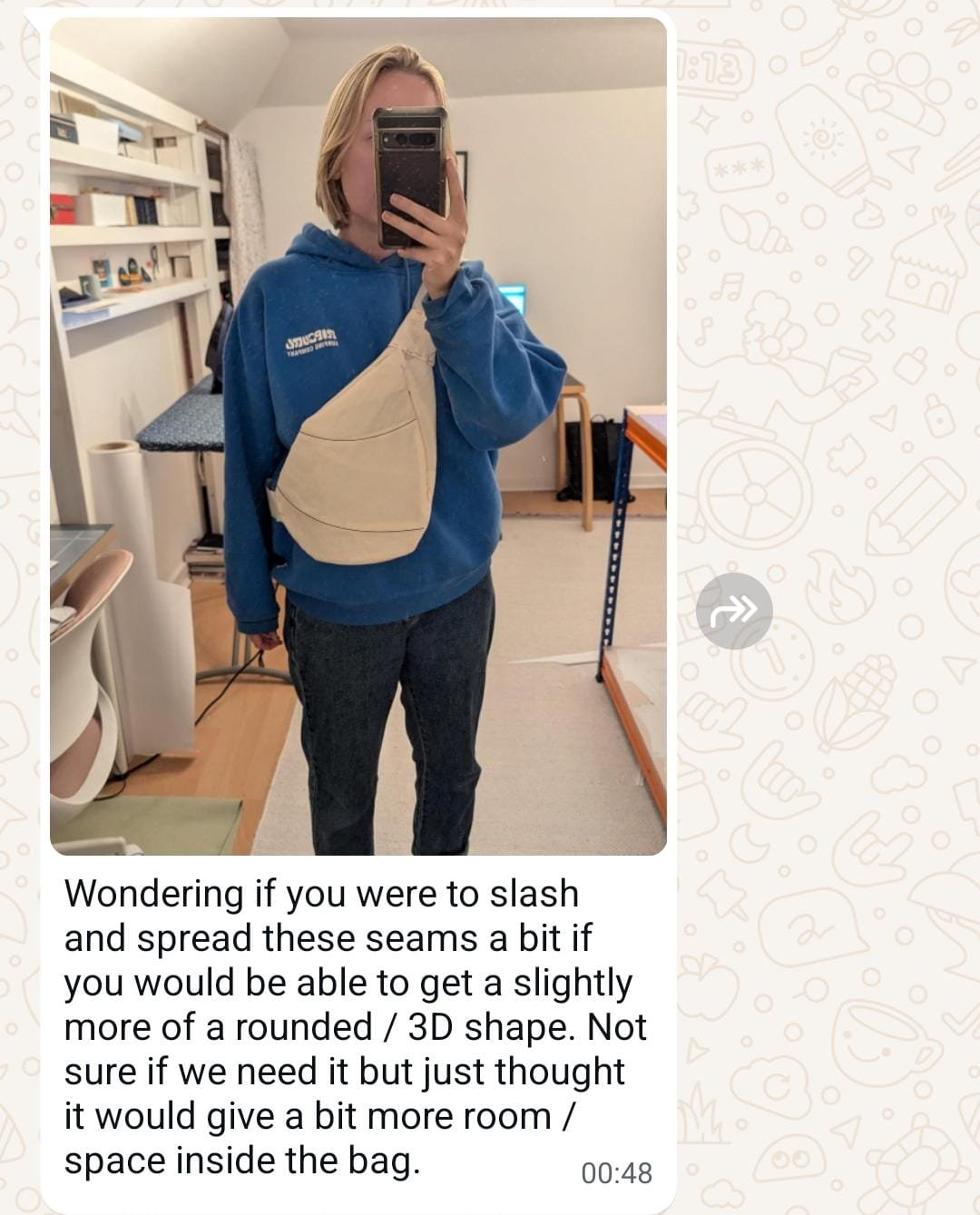

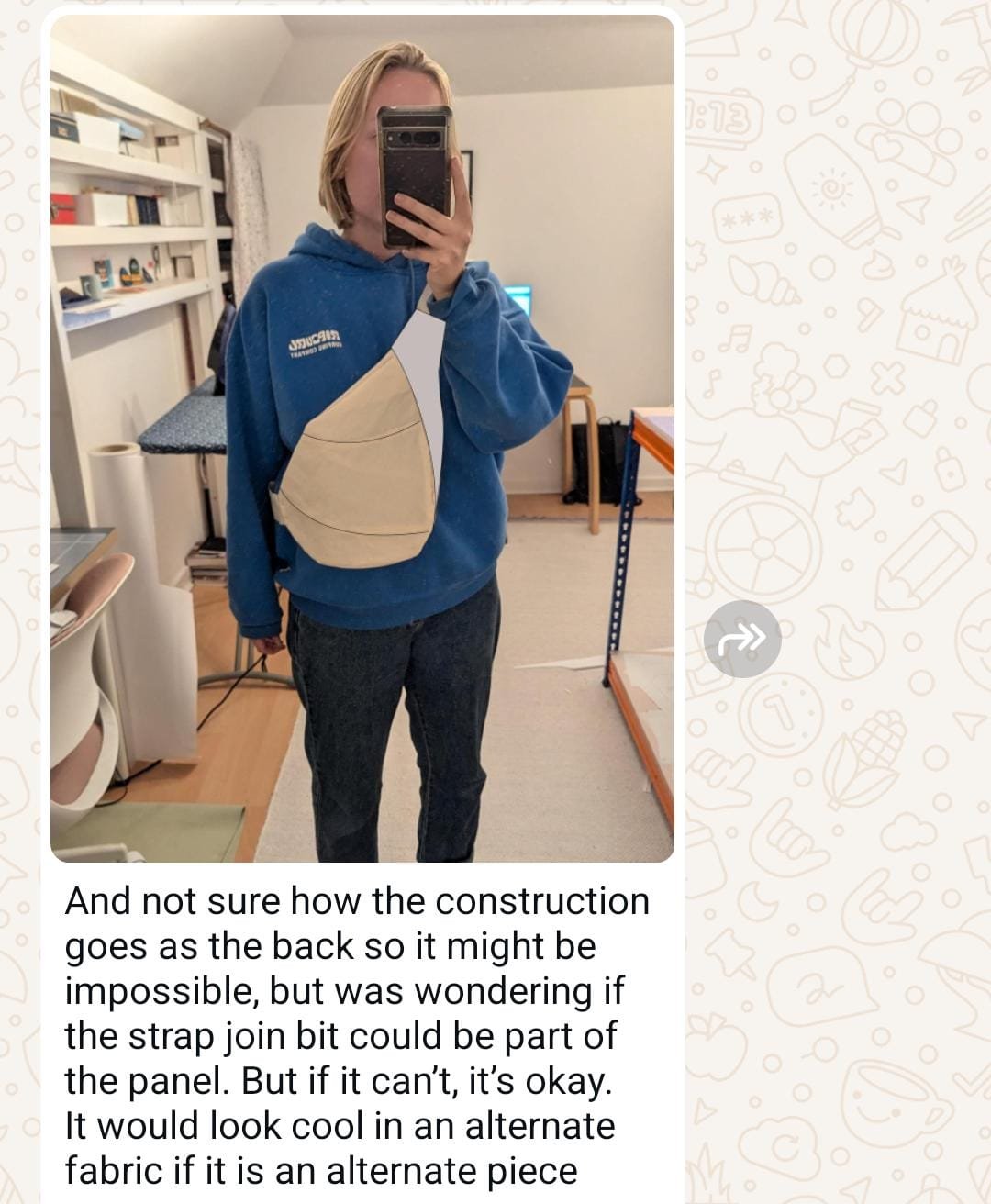

I had been thinking for a while that I’d like to do a twist on a bumbag or crossbody bag, and Alys suggested we use the Darlow pants as inspiration. She thought the curved seams would make for a really interesting design with the panels twisting around the bag, and I agreed.

Following this, I shared some inspiration images I’d found scrolling through Pinterest and we discussed which elements we liked. We to’ed and fro’ed with inspiration for a bit, and eventually realised one of the main features we were drawn to was interesting strap details connected to the main body.

So with this, Alys got to work playing around with the Darlow pants pattern to see what she could come up with.

Firstly, she arranged the main curved pieces of the Darlow pants pattern and scaled them down to 75% so they were the right proportion for a bag compared to a torso.

She then assembled the three curved pattern pieces of the Darlow pants, and played around with them to see what shapes she could create that might resemble the body of a bag.

Through this process, Alys considered how the bag would look on the body, checking shape, proportion and scale. As you can see, Alys was still working with paper when doing this!

After this, Alys felt it was time to get some feedback from me, which happened to be via Whatsapp very late at night! (One of the difficulties of working with a team on opposite sides of the world!)

After we decided to add some length to the pattern, Alys went ahead and began converting her paper bag into a pattern and sewing up the first sample.

We went back and forth after this via videos and photos to fine-tune the design, making decisions like adding some volume to the pattern and moving the bottom seam so it sat towards the back rather than be visible on the front.

After working on the strap panel, our initial bag pattern was complete!

But this is just the start of designing a sewing pattern. The next stages were finalising the bag construction, which involved many more toiles and samples between both myself and Alys as we continued to fine-tune the design. It ends up being months of work, because we’re always working on a number of patterns at one time.

But we can definitely say that we loved working on creating the Darlow bag pattern together (albeit digitally and on different continents!), and we hope that you enjoy making it as much as we enjoyed designing it!

Happy sewing,

Emily

BEHIND THE SCENES WITH EMILY: teaching at university

About three months ago, what felt like simultaneously, my daughter started sleeping better and going to daycare 4 days a week. As the fog lifted, it felt like a missing part of my brain returned. Suddenly I had time and space to breathe. I started exercising again. I started being able to see beyond the moment in front of me and became excited about what the future held.

I hadn’t slept properly for over 2 years. Pregnancy had turned my sleep into a mess of acid reflux and millions of wake-ups to pee. I had hoped that not being pregnant would improve things, which it did, until a newborn got in the way! So many people had warned me about how hard the lack of sleep would be, but nothing could have prepared me. Also, nothing prepared me for how long it would go on and how lonely it would be as the only one who was able to settle my daughter when she woke at night. The photo below was taken right in the thick of it!

Everything I tried to do became a struggle and I found myself doing the bare minimum. But being so deep in it that I didn’t really realise that I was only barely functioning. And then, as I said, my daughter started sleeping better around the time she turned 2 and things drastically changed.

But this post isn’t about baby and toddler sleep. Enough has been written about that and we’re not here for that, are we?! This post is about what has been happening since I started getting a bit more sleep.

When the fog lifted I suddenly felt capable again.

Capable of working on new and bigger projects.

Capable of moving house. (We had outgrown our one bedroom apartment a long while ago but the thought of moving never even dawned on me because I was so exhausted.)

Capable of exercising and socialising. And when I was offered two subjects to teach and UTS this semester, I thought, why not?

I probably should have realised that I could say yes to things, but maybe not all at once! But, there is something so exciting and liberating about feeling parts of my pre-motherhood life return and watching how my new and old life integrate together - sometimes smoothly and sometimes not so smoothly.

And although I am now feeling spread a little thin, and having to say no to some things for the moment while I ease into this new season, I also feel excited and inspired and more connected to my practice than ever before.

I am now teaching first year construction (sewing) at a Sydney university and have loved being forced to go back to basics. Being questioned about how to do things that my hands committed to muscle memory many moons (in fact multiple decades) ago is humbling. It is allowing me to practice my teaching skills and my ability to simplify information. Teaching has reminded me how important clear, step-by-step instructions are—just like the ones I strive to create in my patterns. How many steps make sense to sew an invisible zip? Will my students get overwhelmed if I baste it and then sew it with an invisible zip foot in one demo or should it be split? These questions feel ingrained in what I do for In the Folds. Although I don’t teach face-to-face with In the Folds, my mission is to design instruction booklets and content that feel like I am there with you in the room, so it does feel as though it’s using the same part of my brain.

The other subject I am teaching is Advanced Technologies in fashion, which is a 3rd year university subject. For this subject, I’m teaching CLO3D (a pattern design and visualisation software) and enjoying working alongside the students to make their ideas a reality. What’s really been lighting me up in this subject is the lecture series. I’m sure I must have attended countless interesting lectures when I was doing my degree, but probably by the end started taking it for granted. Now going to these lectures leaves me feeling blown away by all the information. I often think about how thrilled my fellow sewists would be to be in the room with me, so I thought I’d compile a list of some of the interesting things I’ve heard about recently.

university LECTUREs i’ve loved

We had a great lecture about zero waste fashion by Timo Rissanen. He co-wrote Zero Waste Fashion Design. Although I think about the environmental cost of fashion often (and it’s the reason I work in the home sewing space instead of the fashion industry), I enjoyed going back to basics as well as being introduced to some new designers in this space. It’s quite disturbing that the global fashion industry produces more than 100 to 150 billion items of clothing per year. Australians buy an average of 56 new clothing items a year which I found both shocking and disturbing.

Some of the work he referenced in his lecture:

Make / use (open source zero waste patterns you can access)

Holly McQuillan: Weaving Multimorphic Textile-Forms - video here

Timo Rissanen - Designing Endurance (check out those pattern pieces! I am in awe of the placket shape. I asked him about it and he said sewing this shirt is not for the faint of heart!)

Pablo Alejandro Maas - traditional suits meet zero-waste pattern cutting. Scroll to the bottom to seYeohlee Teng's "Zero Waste" Philosophy: Thoughts on her roots, the future of fashion and Japan - TOKIONe an amazing layplan!

zww.fi - a website where you can download free zero waste patterns

Timo ended the lecture on a high note, asking the question, “How can fashion be joyful without overconsumption?” I’d like to think that by sewing our own clothes, we are doing a pretty good job of that. Bringing joy to the making process as well as the wearing process.

Martina Ponzoni told us about her d_archive project where she and a small team are digitising patterns from inside fashion archives so that these artefacts can be cared for, but also so that people from all over the world can gain access to them. I was blown away that these images are actually created digitally, rather than photographs of the original. What’s cool about this project is they make the patterns accessible for people to use!

Wajiha Pervez talked through her PHD research area, which is on circular economy innovation in athleisure clothing. She uses AI to help generate the most exquisite knitwear.

What I enjoy about teaching is how it pushes me beyond my usual routine and into new ways of thinking—engaging with ideas, techniques, and perspectives I might not have encountered otherwise. It challenges me to break down my own knowledge, question assumptions, and find clearer ways to explain concepts. In many ways, it reminds me why I love learning, and why I love sharing that learning with you—whether through the patterns I create, the instruction booklets I write, or the behind-the-scenes insights I share here.

The more I teach, the more I realise that learning is never a one-way street. Just as I guide my students, they also push me to see sewing in new ways, keeping my passion for this craft fresh and ever-evolving.

Happy sewing,

Emily

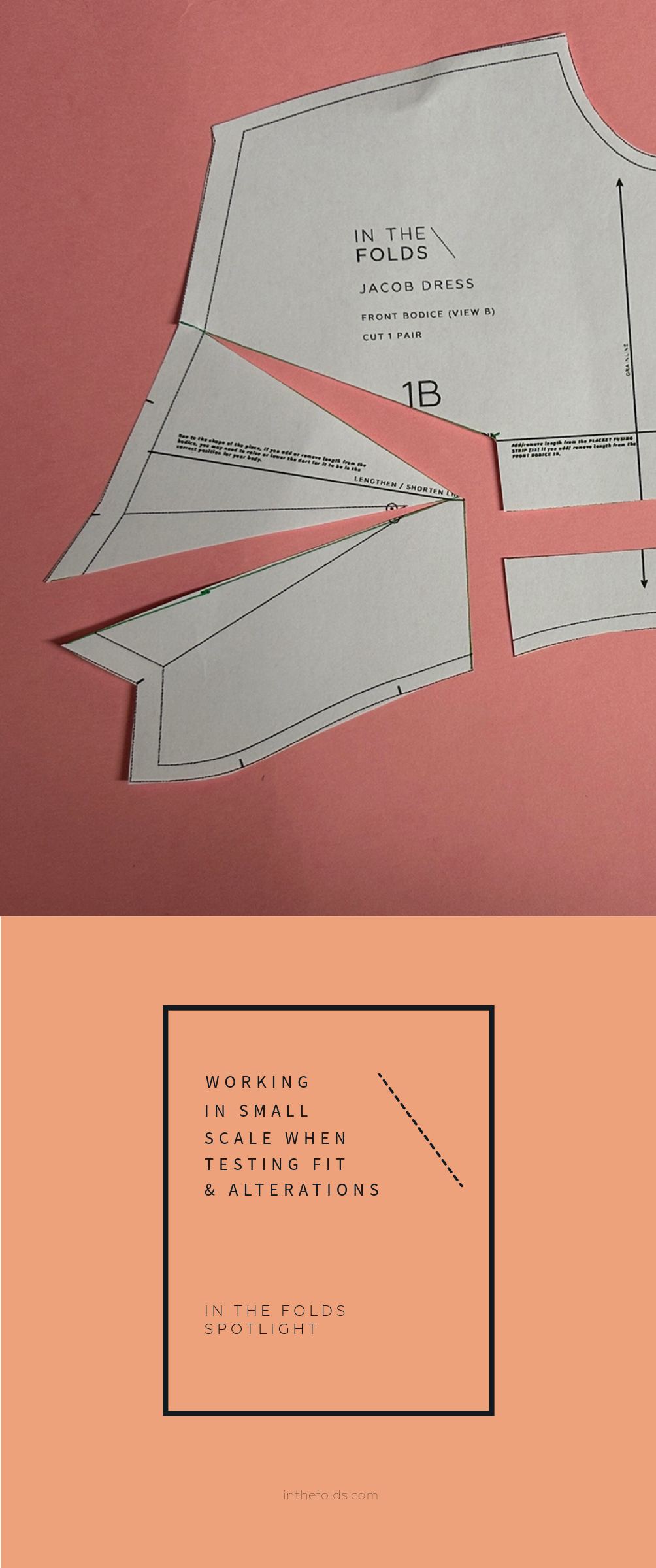

SPOTLIGHT: WORKING IN SMALL SCALE

When I was given my sewing and patternmaking kit in my first year at university, it included all the tools I would need for my patternmaking and construction classes. It had an array of different rulers, a tracing wheel, stiletto (also called an awl), pattern notchers, machine needles, a bobbin and bobbin case, pin cushion, tweezers… and the list goes on.

One of the rulers was a small ruler with markings I didn’t quite understand. On closer inspection I realised it was a third scale ruler. It was marked so that it could be used like a regular ruler, except the markings were in 3rd scale, where 5cm was actually 1.7cm etc.

At university we had huge work tables to do patternmaking, but at home many of us just had a small desk. By working in third scale, we were able to practice our learnings at home in a smaller space, using less materials. It also meant that we could put our work in a binder and see at a glance what the technique was about - rather than folding up a huge full scale pattern that would have to be taken out of a plastic sleeve to see what it was about.

Although I don’t use third scale patterns in my drafting process anymore, I often return to the principle of it. If I need to figure something out, I print the pattern at a small scale and give it a go. For this purpose, it doesn’t need to be exact as I’m just using it to help me figure things out. For example, it’s very helpful for deciding where a design line could go, or understanding how a bust adjustment will work on a particular pattern. It’s also very useful when I receive customer service questions about alterations, because I can give it a go before passing on my advice.

Working in small scale can be used as a fitting tool or a design tool, or a mixture of both.

SMALL SCALE PATTERNS AS A FITTING TOOL

When sewing a pattern, you may decide to do a particular fitting alteration that you’ve never done before. Working in small scale gives you a chance to do a practice run and figure things out. It’s also great to have with you when working in full scale as you can refer back to it.

Small scale patterns as a design tool

There’s less at stake when working in small scale. It’s easy to try different approaches - different dart location, different panel line positions etc - because you can always print another copy. You might surprise yourself and come up with something really interesting just by cutting into the pattern!

As I was working on this tutorial I came up with the idea of moving the dart to the neckline and transforming it into a princess seam. This wasn’t my plan when I started but the idea came to me as I was working and suddenly I’m excited at the idea of a princess panel running from the neck, through the bust to the waist.

You can even sew up small scale examples in fabric if you want to! But be mindful that the seam allowance gets very small. You may prefer to add a bit more seam allowance onto your mini patterns to make the sewing process easier.

How to create a small scale pattern

We include small scale patterns in our Hack Kits (like this month’s Jacob dress Hack Kit) so it’s ready to go, but if you are working with a pattern that does not have this, here’s what you need to do:

Open the A0 file, choose a size (it doesn’t really matter which one) and turn off all the other layers. Adjust the size in print settings to ‘fit to page’ and print.

Use a ruler and pencil to draw in the alteration lines as you would in full scale.

Cut into your pattern and experiment.

Take photos as you go so you can refer back to them when working in full scale later on.

The advantages of working in small scale:

Saves resources – Testing on a small scale reduces paper and even fabric waste, especially when experimenting with complex design changes.

Saves time – Making adjustments on a smaller pattern is much faster than working with a full-size version, allowing for quicker and multiple iterations.

Easier to visualise design changes – A scaled-down version helps you see the overall silhouette and proportion before committing to a full-size alteration.

Reduces cost – Since you use less fabric and other materials, small-scale tests are a budget-friendly way to explore new ideas.

Encourages learning and skill-building – You can practice tricky techniques, like bust adjustments or drafting princess panels without having to work in full scale. This can go even further and also be done in fabric to practice new skills like: pleats, gathers, or draping, without the full effort of a life-size garment.

Encourages creativity – Since it’s a lower-stakes process, small-scale prototyping can encourage more creative risk-taking.

Helps with pattern drafting adjustments – If you're making structural changes to a pattern, a small-scale test lets you check proportions and relationships between pattern pieces before committing to a full-size draft.

What do you think? Can you imagine using this technique in your sewing practice?

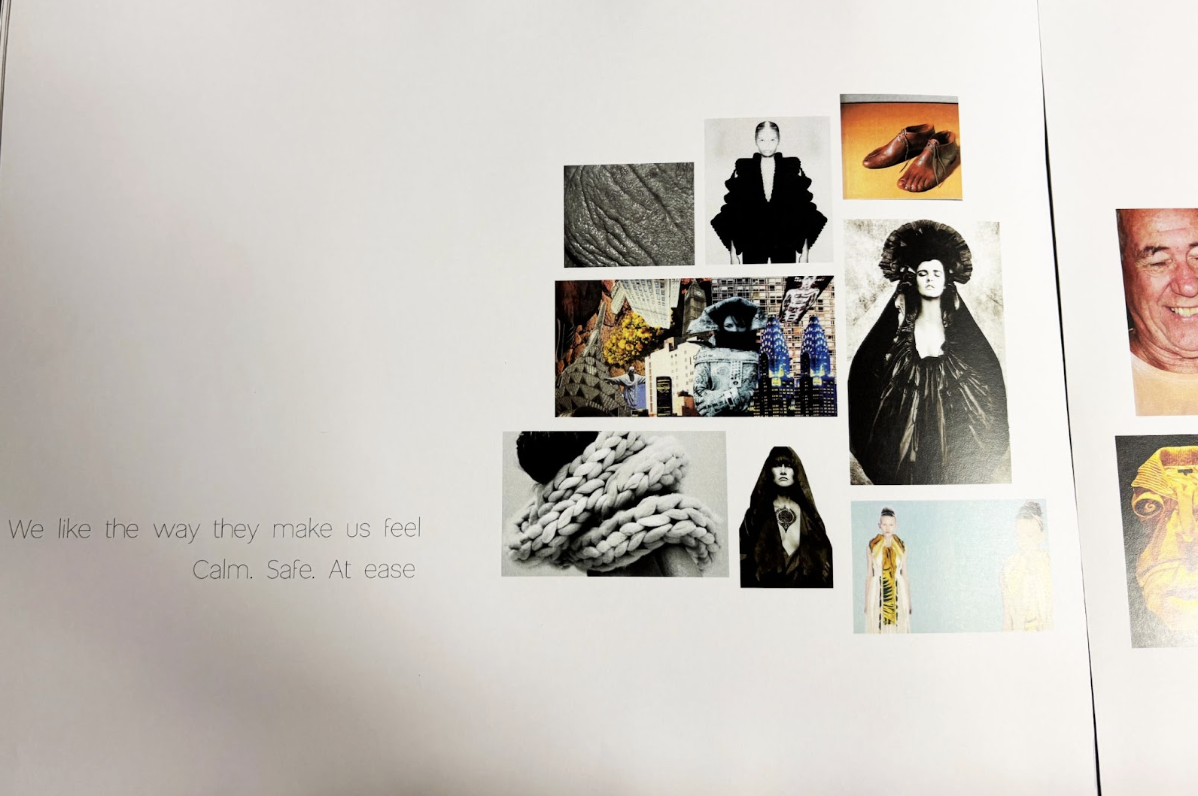

BEHIND THE SCENES: EMILY'S DESIGN DEGREE GRADUATE COLLECTION

When we were thinking about things we could share about the process of designing the Jacob dress, it occurred to me that drawstrings, and the way they can alter the silhouette of a garment, has been something that has interested me since long before I started designing this pattern.

I graduated university in 2011, and my graduate collection incorporated this idea. To put this article together, I went rummaging through boxes and samples to see what I could find to share with you. Unfortunately the photographs of the collection are buried deep on an old laptop (which I may or may not be able to locate), but I did find the printed copy of my portfolio!

As I flicked through the pages, I couldn’t believe how much of my design intention and approach to clothing hasn’t changed, and how much of this ethos is now part of In the Folds.

The collection was based on my grandparent…

““The collection draws upon their physical qualities, their personalities and personal narratives in an attempt at embedding human qualities in clothing.

The collection is about questions and challenging our expectations of clothing. We expect it to cover the body, to fit, to look good and feel nice on the skin, but we do not expect it to meet our other human desires - to touch us, to hold us, to comfort us, to entertain us or to engage with us.

Through attention to detail on both the inside and outside of the garment, the collection encourages people to build a stronger connection to their clothing. Each piece is filled with subtle details, which encourages individuals to explore the pieces and get to know them as if they were a new friend.””

I have included some of the initial design work I included in the portfolio. I was interested in the beauty of aging and how my grandparents’ faces said so much about the way they had lived. I had a very close relationship with my grandfather (he passed away in 2021), and still do have with my grandmother. I loved imagining a world in which garments could convey this love and safety.

While experimenting with ideas, I decided that using drawstrings would be an interesting way to convey this idea of being held, but also show the way a garment can transform in shape over time.

A dress can go from having a loose, low hanging neck, to a gathered high neck.

A dress can go from having large, loose hanging pockets, to a dramatic silhouette (don’t worry… I’ll never release a pattern with pockets like this!)

Looking through the portfolio, I can see the beginnings of some of our patterns! The curves and shape of the Darlow pants, the Flynn and the Hove jackets. I see ideas that I have explored, but which have not made it to the stage of patterns we’ve released.

I see shapes and ideas that still excite me, that may or may not find their way into my work one day.

The portfolio ends with:

““And we realise that what we love about them are the little things. The things that some don’t even notice…” ”

It feels like something I could write about In the Folds patterns today.

The things that I focus on when I’m designing that give makers a kick, a sense of satisfaction, a feeling of pride when they sew them and when they wear them - but that others may not even notice.

What do you think? Can you see a direct correlation too?

TIPS FOR COPYING A PAIR OF PANTS

Hi Emily,

I have a favorite pair of pants and would like to replicate them without taking them apart. Is there a way to do that? Thank you.

DD

Freeport, US

Today’s Spotlight email is a little different. We usually use this email series to focus on a particular technique or element of our latest release. But, we received this question recently and thought it would be a great opportunity to put the spotlight on our recently released standalone resource, the Copy Your Clothes Series.

We've all had one of those garments that we just wear over and over… and then it starts falling apart. And even if we use our best attempts to mend it, it's just too late. Or, a garment that we'd love to make in a different fabric or colour. In this resource, we show you how to take that beloved garment and make a pattern from it.

What's great about copying your clothes is that you know how the garment fits from the original item. Once you’ve created the pattern from the garment, you can adjust it to fit your body better or alter the design to suit your style or preferences.

Overall, drafting a pattern from a finished garment provides a great opportunity to learn pattern making skills without having to start from scratch. And what makes our approach even better? You don't need to take the RTW garment apart to do it!

We’ve already shared some tips for copying your clothes here, but read on for a few more.

Tips for making a pattern from an existing pair of pants

I will start by saying that pants wouldn’t be the first garment I would suggest copying to get the hang of this process. It’s better to start with something simple (like a t-shirt) and work your way up to pants once you’ve got the hang of it. If you want to give some simple garments a go, this is the approach we use in our Copy Your Clothes Skills Kit.

Get your tools ready.

The most important piece of equipment for copying clothes from an existing garment is a needle point tracing wheel. There are various types of tracing wheels available, but it is important you get one with needle points. Ones with smoother or flatter points won’t have the desired effect and are used for different processes in sewing. You need a tracing wheel that is sharp enough to transfer markings through the garment.

Prepare the garment.

Make sure it’s clean and pressed. Don’t skip this and take time to press it well! Starch if needed.

Find the grainline.

Pants don't normally have a straight CENTRE FRONT or CENTRE BACK seam, so the grainline on a pair of pants may not be obvious. To find the grainline, examine the weave of the fabric. The warp threads (lengthwise threads) are usually parallel to the straight grain. Alternatively, if the hem on the pants is straight, the grainline is normally perpendicular to the hem. Once you identify the grainline, use masking tape to mark it.

Get the garment as flat as possible and pin seams to the paper.

When pinning the FRONT, it is likely that the BACK piece will extend past the seams towards the front. Be mindful of this and pin along the FRONT seams, rather than on the fabric extending from the BACK.

Use a tracing wheel to trace around the seams.

Trace around any details such as pockets. Remove the pins and garment and trace the markings made by the tracing wheel with a pencil.

Trace the BACK pattern piece in two parts.

It is common for the back of a pair of pants to be wider than the front due to the fullness of your hips / butt. Be methodical as you trace the back. Use masking tape to mark the fold line on the pants so you are able to trace the remainder of the piece.

Consider the best way to create the waistband pattern piece.

For shaped waistbands, we recommend tracing from the garment. For straight waistbands, drafting the piece using measurements will give a more accurate pattern piece (we show you how to do this in the resource).

Draft the pattern pieces.

Some pieces will be easier and more accurate to draft from scratch rather than tracing from a garment. We have included a range of tutorials in the resource so you can draft the required pieces. Alternatively, you may choose to take elements from patterns in your stash if you like a particular design detail or constructions details. If your garment has a fly front, we suggest borrowing pattern pieces from another pants pattern instead of tracing.

We’ve got a tutorial for drafting pocket patterns here.

Check and true the pieces.

This is a very important step when drafting patterns from RTW garments and we’ve got a tutorial here. Walk the waistband into the waist of pants to check it is correct. Mark notches on the waistband at any points of interest (such as darts and pocket positions).

The final step…

Add seam allowance, move notches to the cut line and add pattern markings to each piece.

Phew! Like I said earlier, drafting a pattern from a pair of pants is quite an involved project, and definitely not something we think a beginner should embark on. A slow and steady approach to the more difficult and involved sewing skills is always a good idea, and we show you how to do just that in our Copy Your Clothes Series. We hope you try it and would love to see your finished projects!

Happy pattern drafting!

Emily

HOW TO MAKE TIME TO SEW IN 2025

Over on Instagram we’ve been reflecting on our creativity in 2024. (Check out our posts here - Emily, Leanne and Xanthe.)

One common theme we’ve noticed is a sense of disappointment with what we achieved (or more to the point, didn’t achieve) in our personal creative journeys.

We all lead full and very busy lives. And while it’s easy to say that we just need to ‘adjust’ our priorities to make room for our creative pursuits, the truth is that it’s often easier said than done. There’s bills to pay, kids to feed, washing to do… You know what we’re talking about, right!?

So we thought it would be helpful at the start of the year to share some tips for making room in our lives to sew when time is short.

HOW TO MAKE TIME TO SEW WHEN TIME IS LIMITED

Here’s 7 tips we’ve put together to help you make time in your busy schedule for this creative pursuit you love - sewing!

Not necessarily every tip will be applicable for you and your life. We recommend reading through and choosing those that are easy for you to do straight away. Implementing just a couple of things quickly will be more effective than having grand ideas about implementing all of them and not actually following through with any.

Have your space set up and ready to go

We know this one isn’t an option for everyone (if this is you skip to step 2!), but if you can keep your space set up this will encourage you to sew when you don't have a lot of time to spare. Make sure to tidy up at the end of each session so that it's always ready to go!

Time how long it takes to get your sewing space set up

If you can’t have your sewing space set up at all times, time how long it takes you to set it up. You might realise that it takes a lot less time than you think. Knowing it only takes a couple of minutes, may reduce the barrier / resistance you feel when you’re not sure if you have the time or energy to sew.

If you don’t like how long it takes you to set up, consider things you could do to reduce that time. For example, can you:

Create a sewing ‘go bag’ that includes all the basic sewing tools you need? Then when you have a spare 15 minutes you just need to whip that out with your sewing machine and get going.

Store your equipment in a way so that all the regularly used items are at the front of the cupboard so you can quickly grab them out and get to work.

Keep your sewing machine plugged into a power point (switched off at the wall, of course!) inside the cupboard it’s stored in so all you need to do is pull it out, take off the cover and turn it on? (You might need an extension cord for this one!)

Have a number of projects on the go at different stages, so if you only have a few minutes you could do the hand-stitching that needs doing, or that final hem, or making a start on cutting out or tracing off a pattern piece.

Try sewing in small pockets of time

Try sewing in 10-15 minute bursts. If you're working from home, this might mean sewing for a few minutes of your lunch break. It could mean sewing for 15 minutes before you leave for work.

You’ll be amazed at how much you can achieve over the course of a week. Not to mention how taking 10-15 minutes for yourself like this can make you feel throughout the day.

Sew instead of scroll

A lot of us are guilty of this one (we know we are!) - saying you don't have time to sew, but spending way too much time looking at other people sewing on Instagram!

Consider taking some social-media-free time and using that time to sew. Or, set a timer for your daily scroll, and when it goes off, get your sewing machine out and sew for the same amount of time.

We think social media scrolling can also be a sign of lost motivation. If that rings a bell for you, this post we wrote about finding your sewing motivation may be helpful.

Use project bags

Project bags keep everything organised so that when you do have time to sew, it's all ready to go! To make a project bag you don't need anything fancy - just something that works for you. It could be a clear bag with a zip, or something that can hang in your wardrobe or store in a drawer. Sew your own with our Organise your space project bag, originally shared in Issue 17 of Curated by ITF.

When preparing your project bag, it's great to have the pattern instructions in there (if you normally print these) and any required notions and thread.

Have supplies ready

It can be a good idea to have a supply of neutral coloured zips and thread on hand for when you need them. You can often use a different length zip than what the pattern calls for - just make sure you will be able to get the garment on and off. You can also shorten zips that are too long.

Finally, consider what it is specifically that’s preventing you from diving into this creative pursuit you love.

If it’s a skill that you feel you’re missing or you’re stuck at a particular point in a project, you can always drop us a line!

A couple of times a month we answer sewing questions from our followers in our Q&A posts. You can check out all the questions we’ve answered so far here. And if you can’t find an answer to your question, leave it with us here and we’ll see what we can do!

We’d love to know how you find time to sew in your busy life? Share your thoughts and tips in the comments.

Happy sewing!

Emily

HOW TO FIND YOUR CREATIVE FLOW IN 2025

In preparation for this month’s Curated by ITF project, the Sewing Mindset Journal, I was reflecting on my creativity in 2024. As I thought about it, my initial response was to cringe and question what I had even sewn this past year. My head began to take me down a track of self-judging and disappointment because my creative output felt a long way off where I’d like it to be. As the owner of a creative business it can be easy to set unrealistically high expectations for myself, especially if I start to compare myself to other creatives.

Thankfully, I was able to quickly stop myself from heading down this track too far. And I realised that, in fact, 2024 was a pretty productive year! Especially considering I have a busy 2 year old in tow, I had to navigate an unexpected studio move and am now only working part-time.

Now, as I look back over the projects we have released to our Curated community since January last year, all I feel is pride. Somehow, a condensed working schedule and being able to find my creative flow quickly has allowed me to hone in on what my work is truly about - interesting, thoughtful and wearable patterns for modern makers.

What is creative flow?

The Cambridge dictionary defines flow as a pleasant state in which someone is giving their attention completely to what they are doing, not thinking about anything else, and doing it skilfully and easily.

What does creative flow mean?

To me, creative flow is that feeling of inertia when everything just comes easily and naturally. It’s when I forget to look at the time or check my phone and just fall into the process of making.

It’s when I don’t think too much about the finished product, but instead focus on the step that is right in front of me and trust that my hands will know what to do.

It’s when I remember why I have been sewing and creating since I was a child and why sewing and patternmaking became my career. It’s when I feel like I could never have done anything else.

How finding your flow can improve your productivity

If, like me, you have looked back at your creativity levels in 2024 and felt a little flat, it may be helpful to spend some time considering what you can do to help you enter a state of creative flow.

However, while finding your creative flow can be really helpful for increasing creative productivity, I don’t think that should be the focus. Instead, I think the benefits will be found in focusing on how you feel as a result of finding that flow - the emotional well-being that it creates within you. And if you happen to be more productive as a result, then that’s just an added bonus!

Tips for getting into a creative flow from some In the Folds team members

Emily

1. Making without a deadline. The stress of a deadline can either make or break your flow. I’ve learned that when I have time to just create something without a deadline breathing down my neck, I have more chances of getting into the sweet flow state.

2. Having an organised space. Just being able to move between processes easily without thinking

increases the chances that I’ll sink into that feeling - not having to think about where my tools are or

worrying about tripping over a pile of stuff or an extension cord!

3. Listening to an engaging podcast often gets me into a state of flow. Enough of my brainspace gets used by paying attention to what I’m listening to, so I can just let my hands do what they naturally want to do. If I'm trying something tricky or for the first time, a music playlist without lyrics (like Deep Focus) works better.

Xanthe

As a working mum of four, getting into a state of creative flow is most definitely linked to balance.

I find that if my priorities are out of balance, it can be very hard to enter a state of flow. If I’m trying to

be creative, but I know I really should be doing something else, then it’s almost impossible to find flow because of the guilt I feel about not doing ‘that other thing’. Interestingly, I probably don’t enjoy the creative time as much either! Some things that help:

Setting time aside that’s specifically set aside for creativity

As someone who really struggles with a blank canvas, having some kind of constraint can also be helpful for finding creative flow.

I love a hard deadline. It gets my creative juices flowing because I simply have no choice!

Alys

Bouncing an idea around, finding inspiration and playing with new possibilities gets me super excited about how to put it into action. This excitement and energy kick-starts my flow state, wanting to make that idea a reality!

Now, over to you…

What does the creative flow mean to you?

What helps you get into a state of flow?

How can you intentionally create more of these moments?

We’d love you to share your thoughts in the comments on this post!

And if they’re making you think more about your sewing process and you’d like to dive a little deeper, here’s a page from our Sewing Mindset Journal for you to download. The Journal is a great resource to help you prep for the year ahead. It’s designed to support your sewing journey and help you develop a positive and productive mindset towards your creative practice through various exercises, prompts, and reflections that encourage you to explore your motivations, set goals, and overcome challenges.

Happy sewing!

Emily

OUR MOST POPULAR POSTS FROM 2024

As you know, we love passing on sewing knowledge and answering questions to help makers progress in their garment sewing journey.

Our Q&A series has been a huge part of our sewing content for the last couple of years, and in 2024 we answered over 20 maker questions - many with in-depth tutorials to clarify hard-to-understand concepts and others with our own sewing perspective, experience and knowledge. We also shared more of our sewing knowledge in the Spotlight and Behind the Scenes blog series.

In the private sewing community that belongs to our Curated by ITF members, we answered even more questions - many specific to the projects we released through our subscription, others about sewing in general.

On Instagram (make sure you follow us if you don’t already!), we continued to share our love for sewing with our followers, posting regularly about the ups and downs of sewing life, funny and relatable memes, and of course, more sewing tips and tricks.

So, to finish up the year we thought we’d share a round-up of some of our more popular posts across the entire ITF world. If you haven’t had a chance to read or interact with them, it might be just the quiet moment you need in the coming busy season!

The ITF team will be taking a much-needed break before the new year begins. We’ll be ‘out of office’ from 20th December to 5th of January, during which time we’ll be resting, spending time with our loved ones and hopefully fitting in a little time for some R&R-style sewing!

Thank you for joining us for another year of sewing adventures and we look forward to serving you even more sewing content in 2025!

Take care,

The In the Folds team - Emily, Alys, Leanne and Xanthe

EVERYTHING WE RELEASED IN 2024

2024 has been a huuuuuuge year on many fronts. Sometimes, it’s easy to forget everything we’ve learned and achieved, because all we can see is the tree right in front of us!

So we thought it was important to take the time to appreciate the forest.

What does the forest look like for the ITF team?

This year we achieved the release of 11 (eleven!) new projects in our Curated by ITF subscription and this month we hit the big 4-0. That’s forty Curated by ITF projects! (Check out our past issues catalogue here.) That’s a pretty major milestone for a tiny little team like ours, and we’re super proud of it.

What does the forest look like for you if you’re a Curated subscriber or ITF pattern customer? Scroll down to read exactly what you achieved with the projects you completed.

And, we’d love you to tell us what the forest looks like for you and your sewing journey this year. Tell us all about everything you’ve achieved!

January - Colour Analysis Skills Kit

What we learnt: Why colours can make you feel confident and put together, or uncomfortable and self-conscious. We gained insight into the colours we love to wear, and the colours we feel great in, plus we created colour palettes we can take with us when shopping for fabric or garments. Major confidence booster!

“The personal colour analysis was very helpful and has helped me target my fabric purchases (and save $). ”

February - Elwood dress

Sometimes you can just ‘feel it in your waters’ when a pattern is going to be popular. And our waters were right on the mark with the Elwood dress pattern!

What we learnt: Sewing French seams, bias binding, V-necks, piecing panels together accurately, sewing a raglan lantern sleeve and in-seam pockets with French seam finish.

March - Coat sewing Skills Kit + Ormond apron

What we learnt: How to sew flat felled seams on curved and straight seams, bias binding, welt pockets with French seams, vent openings, hand-stitching, block fusing and piece fusing, grading, clipping, understitching, sewing a facing.

April - Ormond coat

What we learnt: Curved seams, pockets, seam finishes with bias binding, flat-felled seams, interfacing, top-stitching, and the benefit of practicing skills before applying them to the ‘real thing’.

“Ormond jacket!!! Wear it the most and learnt the most. This also includes the apron and incorporated skills which was a really fun month, I loved the low pressure learning while making a very useful item.”

June - Copy your clothes Skills Kit

What we learnt: How to use a French curve, checking & truing patterns, changing the amount of ease in a sleeve cap, adding seam allowance, marking notches, truing darts, adding pattern markings, drafting additional pieces, such as button plackets, slash pockets, straight waistbands, in-seam pockets, patch pockets, sleeve cuffs, neck ribbing etc.

“The copy your clothes and make it your own has been very empowering for many different sewing activities. I feel like my vision/perception has improved as a result of this exercise.”

July - Make it your own Skills Kit

What we learnt: Altering garment fit through grading and darts, dart manipulation, panel lines - horizontal, princess, curved and variations, changing a garment's shape - length, fit, removing sleeves, adjusting armholes, waist height, adding volume, drafting facings.

August - Malvern culottes

What we learnt: How to interpret complex patterns, new pattern markings and symbols, folding pleats, bias bound pants opening, buttons and buttonholes, in-seam pockets, and how different fabrics impact the drape of a garment.

“Malvern is probably the winner for versatility and enjoyable sewing. 🏆”

September - Drafting linings Skills Kit

What we learnt: the purpose of linings, different lining types and how to draft linings for jackets and coats; skirts with waistbands, waist facings, and side splits; and dresses with and without sleeves.

October - Sewing linings Skills Kit

What we learnt: what to consider when sewing linings with unattached hems, buttons, waistbands, zips and facings, lining fabrics and how to achieve a professional finish.

November - Lindon top

What we learnt: French seams, gathers, narrow neck binding, knit fabrics, knit neck bands, and hemming knits.

December - Fairbank hat

What we’re learning: sewing curved seams, working with interfacing, top-stitching and edge-stitching, bagging out and working with unusual fabrics.

WHAT YOU’VE BEEN MAKING…

Marden shirt made by Curated member, Kathy.

Malvern culottes made by Curated member, Tanja.

HOW TO BUY THOUGHTFULLY DURING SALE SEASONS

It’s that time of year when our inboxes are inundated with businesses vying for our attention:

You need this! It’s so cheap! Don’t miss out! You might regret it if you don’t buy it now!