THE Q & A SERIES

MOVING POCKETS ON THE FLYNN JACKET

Hi there,

I've purchased the Flynn Jacket pattern but being 5' 2" tall I'm concerned that the pockets are going to be too low for me.

Do you have a suggestion as to how I can make them higher?

Would appreciate your help.

Steph

Hi Steph,

Thank you for getting in touch.

I am pleased to hear you will be making the Flynn jacket!

I would suggest shortening the jacket all together - this will bring the pockets up to the position you need them. The jacket was designed for a height of 5'7" - so you might want to take 2" or so out of the length. I'd hold the collar / hem piece up to your body to work out the length you would like the jacket to be.

There are a couple of other reasons why you might also want to do this adjustment to the Flynn jacket:

You might be 170cm (5'7") but have a shorter torso and longer legs than the pattern was designed for

You may prefer more of a cropped style than the original design

THE FIT OF THE FLYNN

The Flynn jacket is designed to finish at the top of the thighs (and just below your bum at the back). Due to the design of the hem band and curved front panel, you can’t just simply cut length off the bottom of the jacket pattern as it will change the proportions of the jacket. Instead, you need to take length out from the middle of the pattern pieces, so that the proportions remain intact, and today that is what I am going to show you how to do!

As is becoming quite common with my patterns, the Flynn jacket has some very unique panel lines. This means that making alterations to the pattern is slightly different to what you would need to do with a straight cut jacket. It’s not difficult at all, and the principle is the same, there is just a few extra steps you have to do.

As the Flynn jacket and Hove jacket have style lines in common, you can use this tutorial for shortening the Hove jacket too.

GETTING STARTED

STEP 1

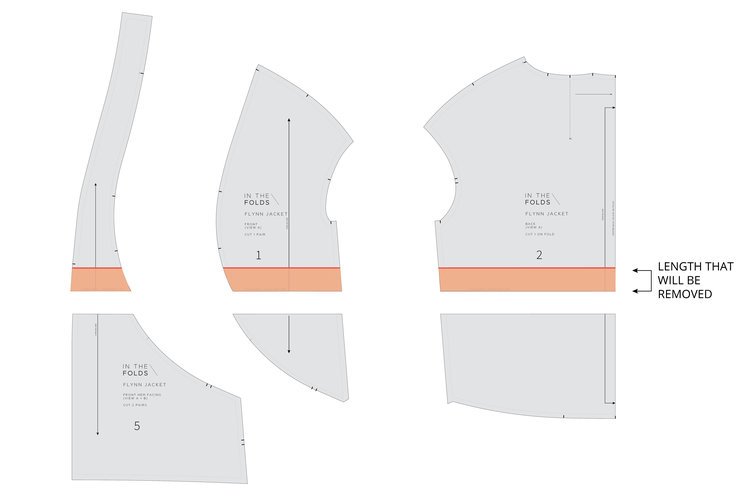

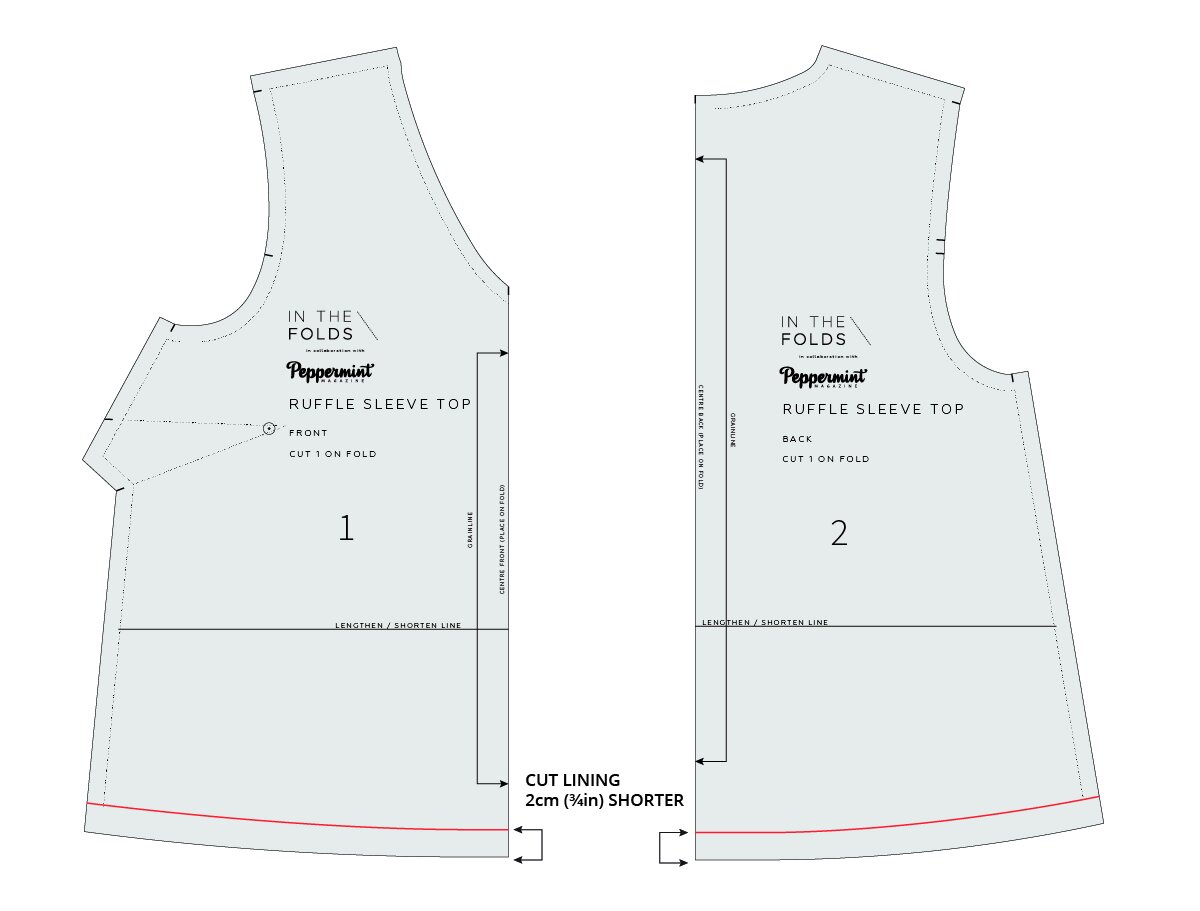

The pieces you will need for this adjustment are the FRONT HEM FACING [5], FRONT [1] and BACK [2] (or the coordinating pattern pieces for View B). You can use the actual pattern pieces, or trace a copy if you would prefer to keep the original pieces intact.

STEP 2

You will need to work out how much length you would like to remove from the pattern. You can do this by looking at your toile / muslin (for more details on making a toile / muslin look at this post from the Rushcutter sew-along), or holding the pattern pieces up to your body and getting an idea of where they will sit on your body.

If you would like to remove any more than 7.5cm (3in), I’d suggest taking 5cm - 7.5cm (2in - 3in) from the mid-section of the pattern (where the LENGTHEN / SHORTEN lines are) and then removing the remainder from the hem band section so that you don't alter the proportions of the jacket too much.

A Cut through the 'LENGTHEN / SHORTEN' line on the FRONT HEM FACING [5], FRONT [1] and BACK [2].

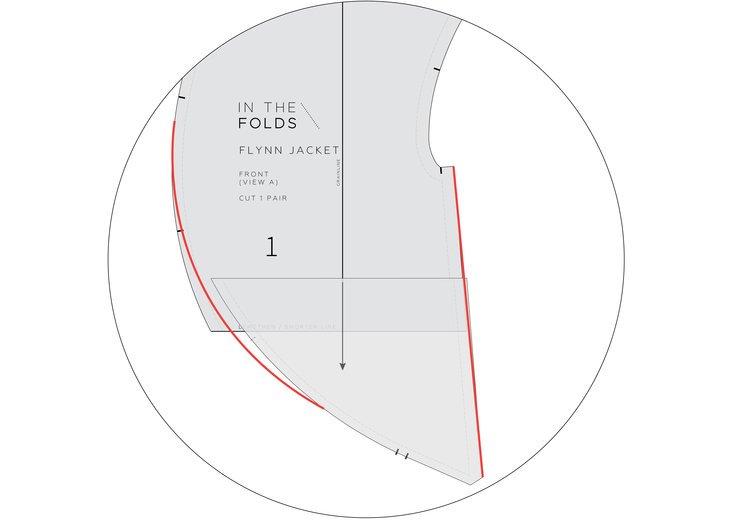

B Measuring up from the cut line, mark a horizontal line on each pattern piece, the distance of the amount of length you would like to remove. In the example, you can see the red line is 5cm (2in) above the cut line and the shaded section shows the amount of length that will be removed from the pattern piece.

STEP 3

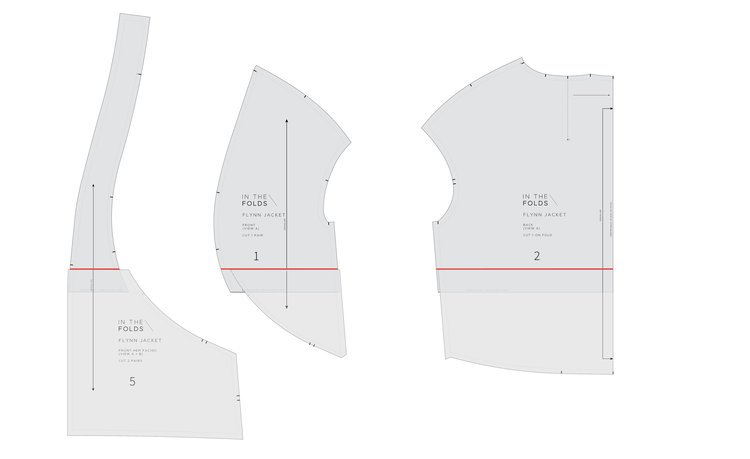

A Move the lower part of each pattern piece up to the line marked in the previous step. Use the grainline to ensure that you line the pieces up correctly.

B Glue or tape in place.

STEP 4

A Re-draw the seam lines with smooth lines over the adjustment. You will notice that in some cases you will be needing to add a little bit on to create the line of best fit, while in other cases you will need to shave a bit off. This will even out as you go around the pattern.

B When marking a line over the area that has been altered, there might be a large gap between the two sides of the line. In this case - split the difference by marking a point in the centre of the area and drawing the line across this point. You can choose to trace the pattern on to fresh pattern paper or tape on small pieces of paper / masking tape where you need to fill a small gap to complete the seam line.

Cut off any excess paper that is outside of the new lines.

STEP 5

Check all seams are the correct length by "walking" the pattern pieces, as if you were sewing them together. For more details on how to do this, check out this tutorial.

Transfer / re-draw any notches that have been misplaced. Due to the shape of the pieces, some notches may not line up due to the different points the alteration was made. After checking that the seam is the correct length, transfer one notch to the other piece (and cross out the notch that is no longer in the correct position).

Happy sewing,

Emily

resources mentioned in this issue

The Flynn Jacket pattern - can be found here.

P.S. Don't have a question, but found this newsletter helpful? I'd love to hear from you! Get in touch and say hi.

For more issues of the Q & A series, you can check out the archive here.

What you’ve been making

Peppermint wrap top made by @sheralcreates

Acton dress made by @stitchinginspace

Peppermint jumpsuit made by @briana_sews

Peppermint wide leg pants made by @russhemade